IMC500 / e-Bus with In Motion Charging (IMC®)

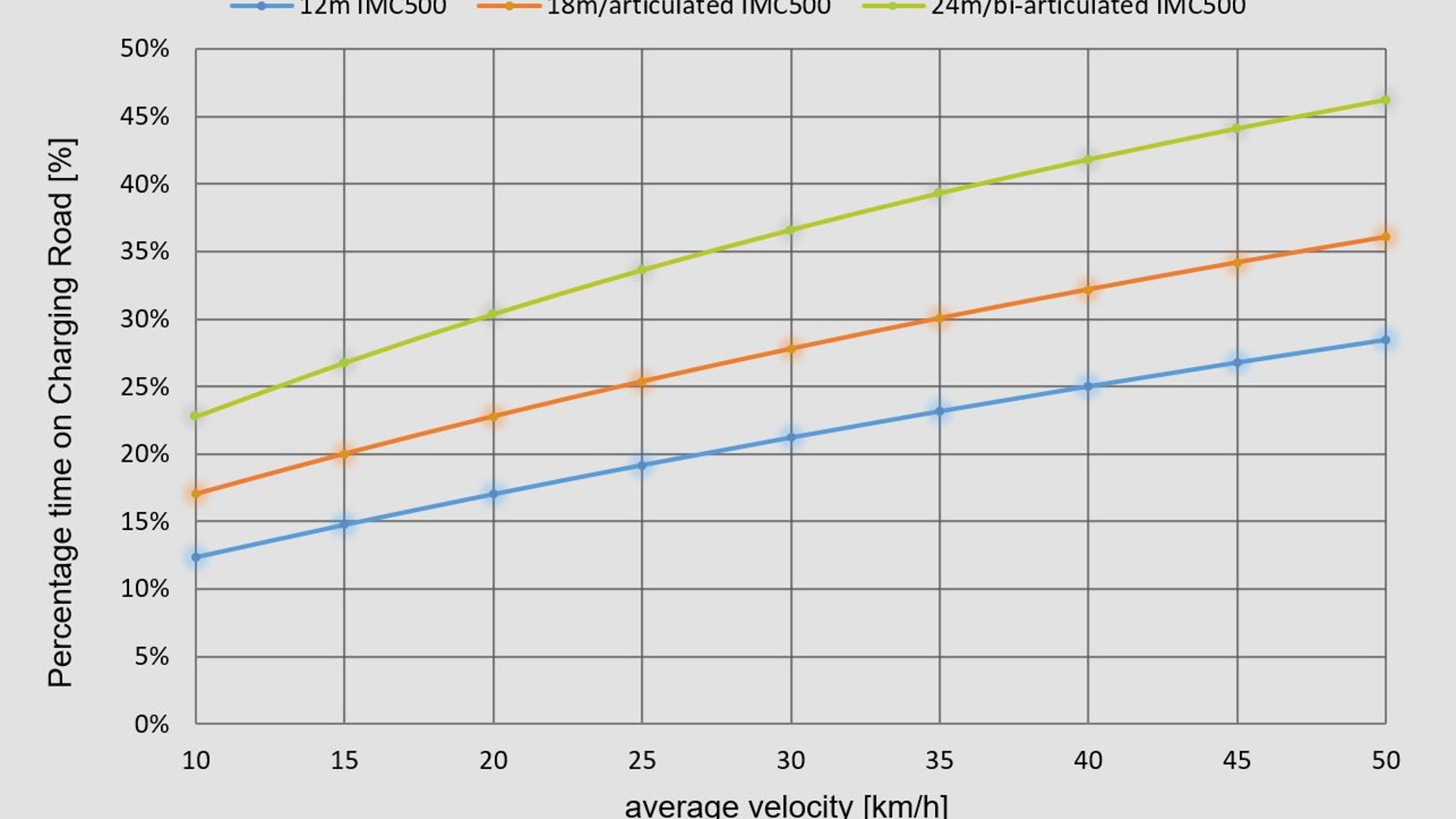

Kiepe Electric is one of world’s leading specialists in In Motion Charging (IMC). The IMC500 allows reliable, uninterrupted operation 24 hours a day. Thanks to the fast charging during the journey, the buses only have to be operated under overhead contact lines 20 – 40 % of the journey time.

IMC500 transfers energy from the infrastructure to the vehicle at a power of up to 500 kW. The e.g. 2 x 160 kW motors are supplied in parallel to the battery charging with e.g. 200 kW.

The energy management is a further core component of Kiepe Electric. Of course, the optimised recuperation of electric braking energy into the batteries is part of our DNA. IMC500 is a very powerful charging system. It is ensured that the power collected from the overhead contact lines does not exceed the power made available by the substations. Overloading is automatically avoided. Moreover, Kiepe Electric’s Smart Fleet-Charging Management (link to SFM) distributes the power supply to vehicles in the same overhead contact line segment according to need of the vehicles.

Kiepe Electric has many decades of experience with the integration of systems into vehicles, which are manufactured by many different manufacturers. Moreover, we have thorough understanding of the interfaces to the charging infrastructure and the overhead contact lines as well as of the requirements resulting from standardisation. Thousands of vehicles perform reliable line service around the world under extremely difficult conditions. The reliability of the IMC buses corresponds to that of conventional diesel buses, which e.g. the operator in San Francisco describes, see https://www.sfmta.com/reports/muni-mean-distance-between-failure

The equipment developed and manufactured by Kiepe Electric reduces the operating costs (TCO) to a minimum and is designed for a long life. Maintenance contracts make life cycle costs calculable and reliable.

The complete system is optimised and delivered from a single source by Kiepe Electric – from the top to the bottom, from the current collectors (link to OSA) to all converters and inverters for battery charging, on-board power supply and drives.

Thousands of vehicles are in rugged line operation worldwide under the most difficult conditions.

FAQ

Why is IMC the most effective e-bus concept?

- Motors, heaters and the complete vehicle are supplied with energy from the overhead contact line when the bus is operated under it, which means that the batteries can be efficiently charged and discharged.

Why is the IMC bus called the bus with unlimited range?

- Because an IMC bus is operated electrically just as a tramcar without limitation of the range.

How economic is the IMC bus in comparison with other electric bus systems?

- IMC is very economic on routes with intensive operation and on sections in which several bus lines are operated. This statement has been confirmed in numerous independent studies.

Video

In Motion Charging-Kiepe Electric IMC 500

How much overhead contact line is necessary with IMC500? In case of IMC500 only 20 - 40 % of the route has to be equipped with overhead contact lines. The exact percentage depends on e.g. the vehicle length and the time that the vehicle is operated under the overhead contact line

Where should overhead contact lines be installed in the optimal case? Simple, straight, low-speed roads are ideal for cost optimisation. IMC can also be supplemented by opportunity charging at terminals with scheduled breaks. New overhead contact lines can e.g. be installed in industrial estates.