Reliable operation of trains and prolongation of their life cycles: The proactive obsolescence management from Kiepe Electric supports the achievement of these customer objectives.

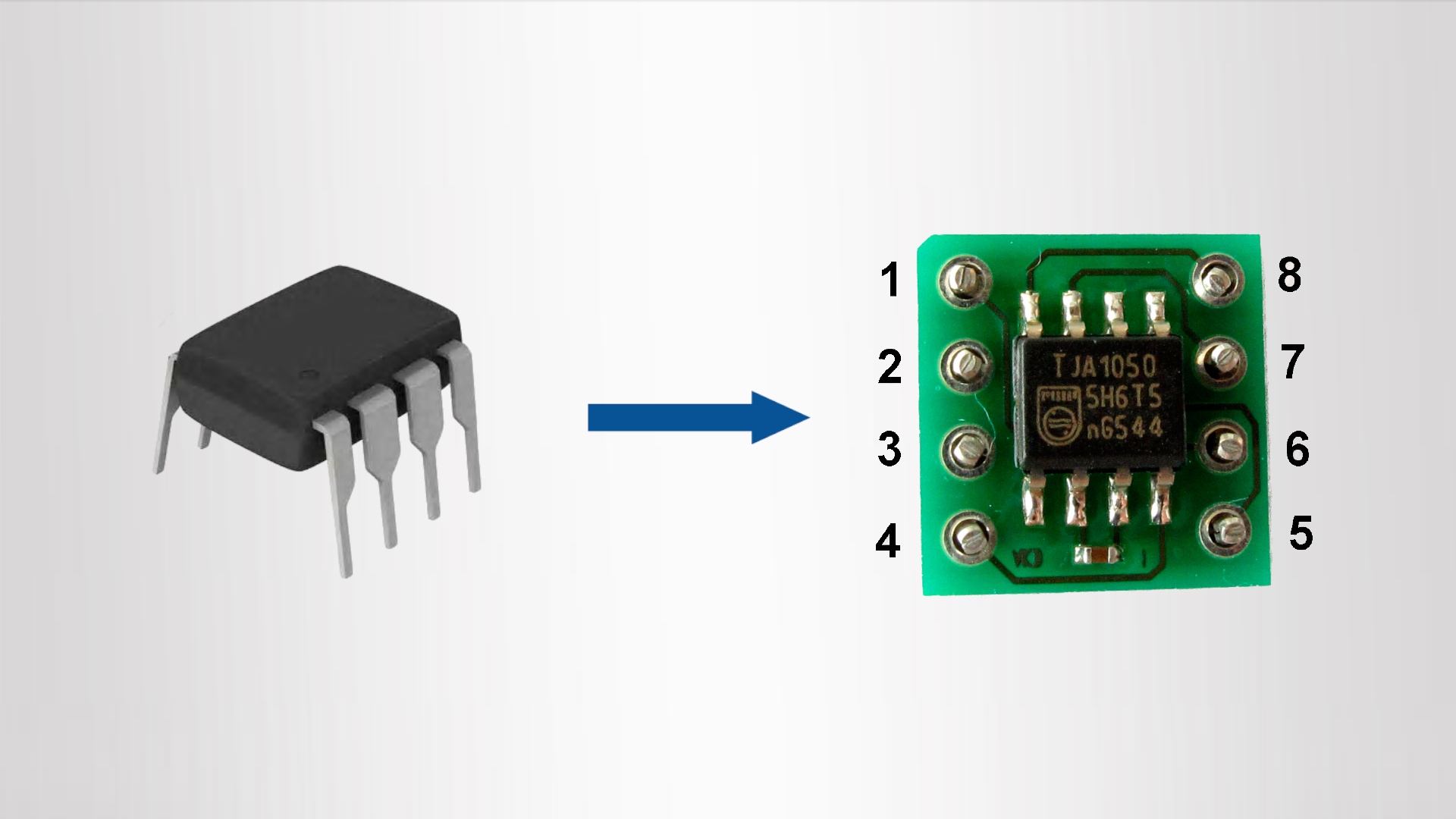

The technological progress and the limited usability of components are some of the reasons why products have to be supported, improved or replaced during their life cycles. Kiepe Electric supports its customers in this respect by way of a sophisticated obsolescence management. Thus, the customers are e.g. early informed about any modification, discontinuation or necessary replacement of components and spare parts.

Thanks to this forward-looking planning, our obsolescence management team ensures that replacement is available in time for discontinued components or that sufficient material is on stock for any upcoming repair. Thus, Kiepe Electric makes sure that the customers have adequate spare parts for the complete useful life of the vehicle.

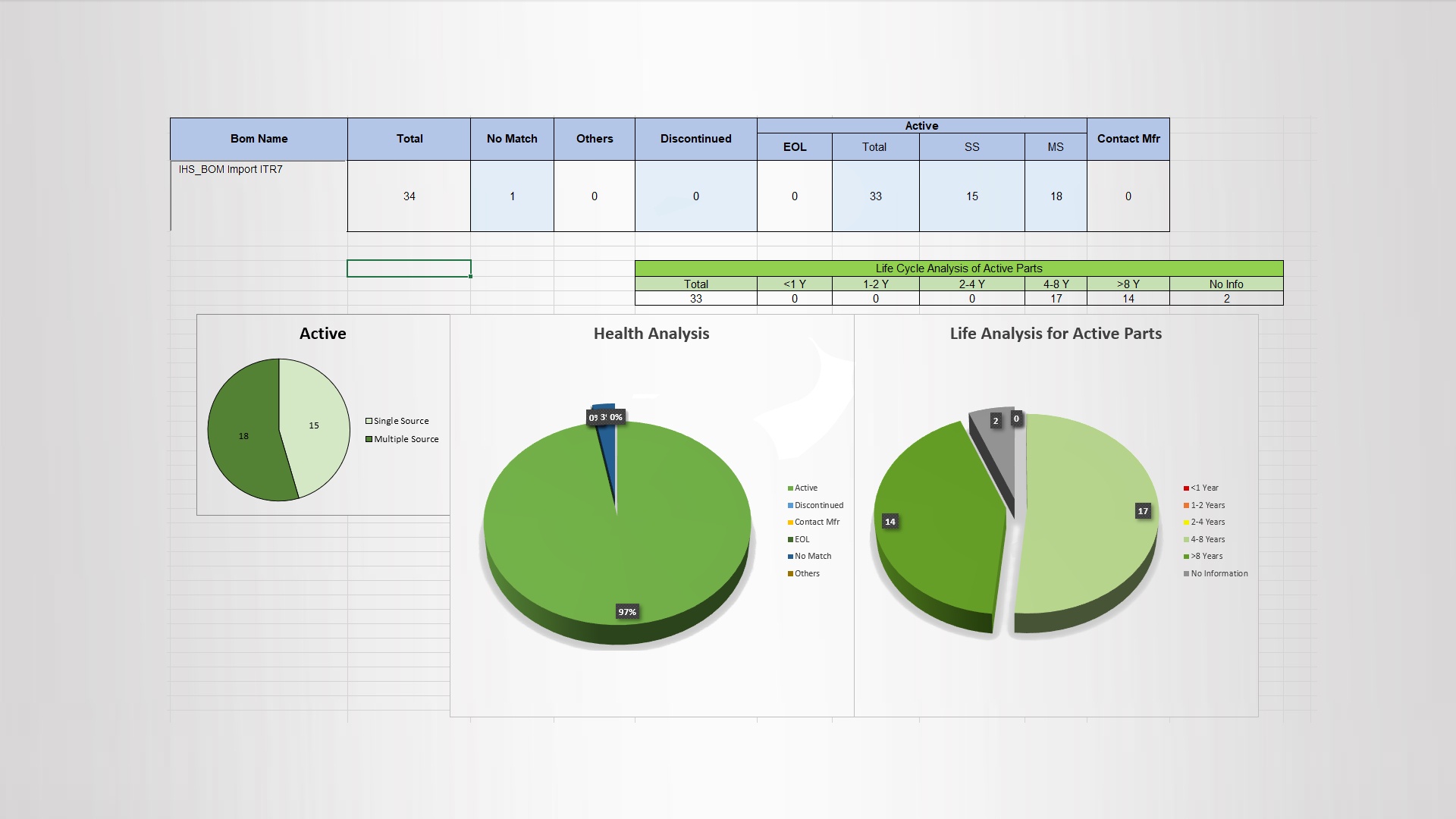

An obsolescence analysis by Kiepe Electric ensures that your obsolescence management is based on facts. Kiepe Electric shall be happy to advise you individually.

Contact us under the following e-mail address. Please also use this e-mail address for the transfer of PCNs and PDNs.

Your contact:

40599 Düsseldorf

Deutschland - Germany

kamil.kubik@knorr-bremse.com